Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

Integrating some level of intelligence into machines has always been at the heart of technology - We are at the forefront of patronizing deep learning, TensorFlow, OpenCV, Robotics & 3D Printing to take a leap into the future to achieve Machine Intelligence.

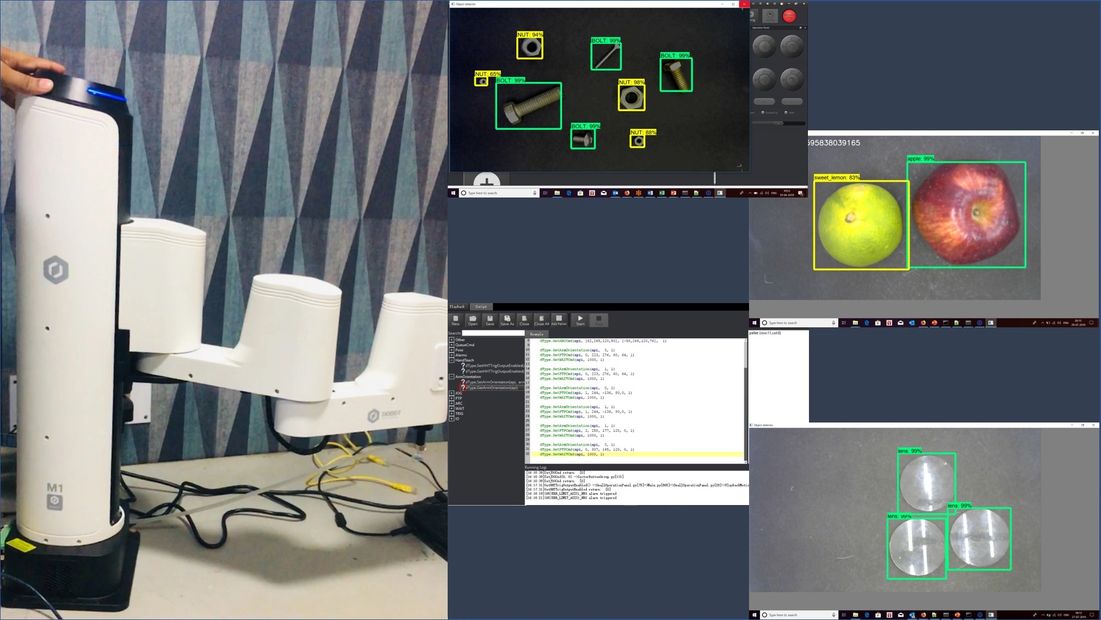

Deep Learning Implementation in Vision Integrated Robotics allows us to identify, class, localize and map various features of interest for Robotic access. We are building framework to push the limits of embedded AI computing devices such as NVIDIA Jetson TX2 to be deployed in manufacturing environment interfacing deep learning vision systems and industrial robotics.This allows accurate robotic pickup of various objects based on intelligence in a factory scenario.

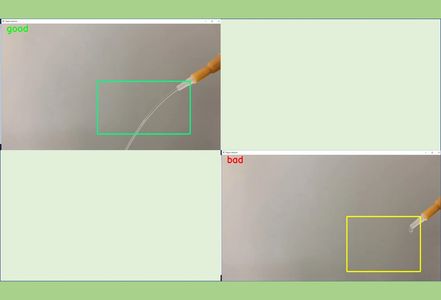

Deep learning vision systems can be applied for even hard to see objects such as transparent lens under changing ambient conditions or for identifying mechanical components such as nuts & bolts or in food grading and sorting as discussed in use cases below.

Trained models identify automotive parts, defects in assembly or process, classify and also map their location for robotic access

Train -> Classify -> LAM (Localization & Mapping)

Identifying transparent objects such as lens is achieved through Deep Learning. Lens are identified and location mapped for robotic access

Train -> Classify -> LAM (Localization & Mapping)

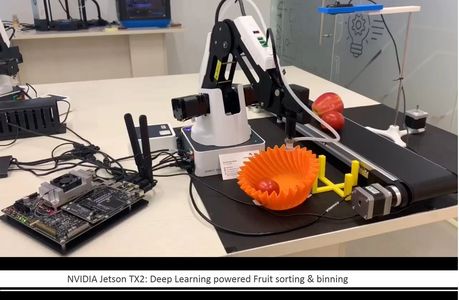

Identifying Fruits & vegetables is achieved through Deep Learning. Fruits are identified by type and location mapped for robotic access

Train -> Classify -> LAM (Localization & Mapping)

Real time visual operational confirmation is achieved through spatio-temporal analysis of scenario through deep learning implementation

Train -> Classify -> Feedback

Lost cost, high performance vision systems used in smart factory Robotic applications are researched, prototyped and programmed.

3D Printing of jigs and fixtures saves tremendous amount of time, effort & cost compared to traditional methods.

Custom end effectors are innovated through design, prototyping using 3D printing, robotic integration and programming.